Drill Compressor

Problem:

Compressor rebuilds were required much sooner that the expected 30,000 hours.

Best-case downtime caused 1 week of lost production. The worst case would take up to 3 weeks.

Solution:

Over the course of three years, $1.26 million was returned to production by reduction of unscheduled maintenance. Improved lubrication cleanliness enabled $546,000 of annual savings in maintenance costs.

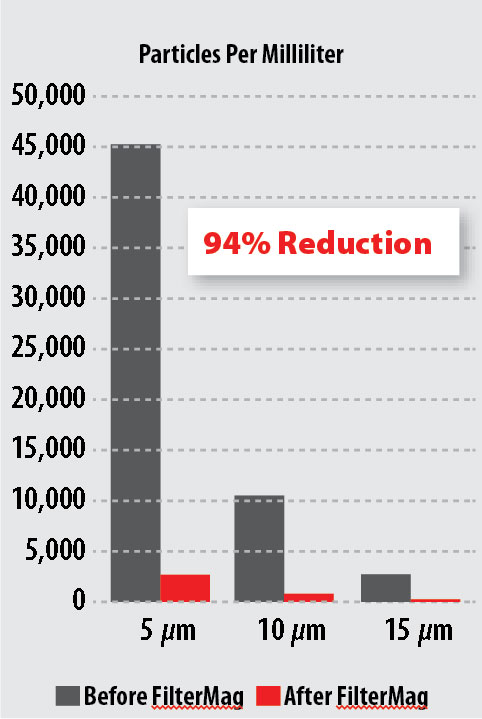

We Found: The twin-screw rotary compressor was experiencing high levels of metal particulates in its lube oil. The filtration system was operating at factory specifications however the unusually high wear metals persisted. This was confirmed by high particle readings from the ISO4406 particle tests.

We Fixed: Solito recommended implementation of FilterMag magnetic oil filtration. They were applied on top of the compressor’s four existing filters.

How We Facilitated Changes: ISO4406 data appeared to be much more responsive to determining particle issues in lubrication oils. Maintenance management saw this as a superior early warning advisor.

How We Facilitated Changes: ISO4406 data appeared to be much more responsive to determining particle issues in lubrication oils. Maintenance management saw this as a superior early warning advisor.

The numbers: Particulate contamination was reduced by 94%. Savings were realized from the additional availability to production at $9,000/hour and the 300% life extension to the compressor from dramatically cleaner lube oil.

Over a three year period:

One week downtime returned to production @ 140 hours/week X $9,000/hour = $1,260,000

Reduction in maintenance costs because of life extension of compressor = $546,000