“Make it work and make it stick!

And by the way, we need it done by the end of the week.

And our budget just got cut by 30%.”

Before Solito

What are your top three issues gating productivity? They have to be measurable. If they aren’t you haven’t gotten to the bottom of the problem.

We will help boil down your issues to manageable pieces that have well understood costs. Their priorities combined with budget constraints become the first pass at delivering the highest value production returns for your maintenance dollars.

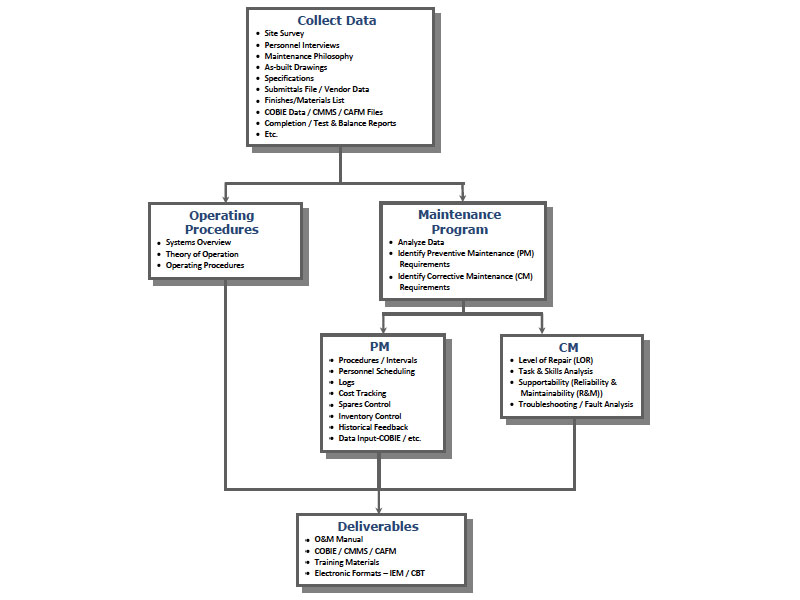

The following tools can be used to help deliver the best bang for your maintenance buck.

Nobody knows your equipment better than you do. But sometimes a second set of eyes sees things differently.

Our depth of experience from many industries, processes, and types of equipment helps us envision best practices for your unique environment.

The result of this survey becomes the basis of how we sit down with you and develop a custom solution for you.

Your maintenance practices are already good. Getting to the next levels may require a review of current processes.

Starting the process can be very simple. Identify your top issues that you can define. If you can’t, go down to the next level of detail until you can define them.

The good news is your issues may have already been solved by us at one of our other customers. Allow us to help.

Some failures require a deeper level of understanding. You need to know how and why the failure impacted your operation.

When appropriate we can assist you in performing the RCFEA. These results typically play a very large role in the determination of your solution.

We can help you set it up. We aid in finding the lube issues, help develop a fix that can last, and then help you make sure they stay fixed.

Are you short of manpower and/or internal expertise? Allow Solito to provide a complete solution from inception to full integration into your processes. We can do it all for you. The container pictured is effectively a new lube room replacing a 40-year-old system that was beyond repair.

You know reliability of your spares is critical. Have you seen these issues:

The longer spare parts and lubricants sit in storage the more likely they are to fail, unless they have been properly maintained.

What is proper maintenance for spares? Consider these examples:

We offer cost effective and simple solutions. We can help you:

OR we can simply maintain your spares for you. Preventing the failure of one critical part can often pay for a full year of spares maintenance.

This is the core of making sure repairs stay repaired. We train with lubrication specific courses created by Noria Corporation.

Additional course work can be created to embrace your special situation.